The FIT Suite: Training materials and Annex

by ILO

created

2021-09-09T03:52:06+07:00

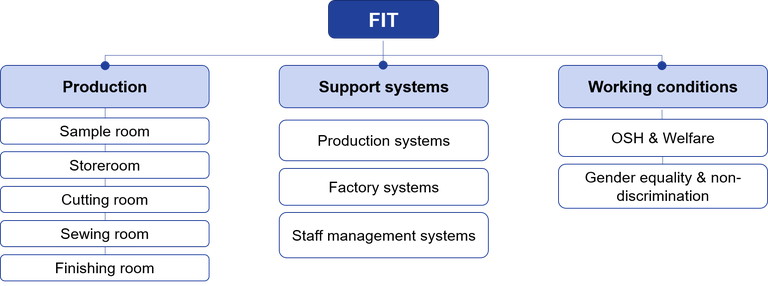

The FIT suite consists of a wide range of learning modules, divided into three categories; production, support systems, and working conditions tools. In addition with the modules you will find Annex materials related to specific modules.

Find below all available FIT Tools to download in English. Want to download the FIT Tools in Bengali, Chinese or Khmer? Click here!

|

Introduction |

|

|

SERIES: Production operations |

|

|

Sample room operations |

|

|

Storeroom operations |

|

|

Cutting room operations |

|

|

Sewing room operations |

|

|

Finishing operations |

|

|

SERIES: Support systems |

|

|

Production systems |

|

|

Factory systems |

|

|

Staff management systems |

|

|

HR11-Trust in Teams |

|

|

HR12-Setting Priorities |

|

|

HR13-Managing your time |

|

|

HR14- Teamwork in Factories |

|

|

HR15- Building Agreement |

|

|

HR-16-Working effectively with Managers |

|

|

SERIES: Working conditions |

|

|

Health & Safety |

WC1 - Introduction to OSH |

|

WC2 - Better ergonomics |

|

|

WC3 - Improving welfare |

|

|

Gender & Non-discrimination |

WC4 - Dealing with sexual harassment 1 - Raising awareness |

|

WC5 - Dealing with sexual harassment 2 - Preventing and addressing |

|

|

WC6 - Inclusive factory practices |

|