"You either invest to catch up, or you are at risk of running out of business"

In your report you state that the core technology of Industry 4.0 is not the computer itself, but the internet. What exactly is meant by the term Industry 4.0, and what does it look like in the Cambodian garment sector?

There is a lot of misunderstanding of the term. Sometimes it’s associated with having an application on a smartphone. But as the term coins it, we are talking about a change in industry; the way products are manufactured in factories. The change here refers to complete connection from consumers to the machines in the factories. Imagine you can design a pair of shoes yourself in an app and they are automatically produced by interconnected machines and delivered to your house by a drone.

What risks and opportunities does Industry 4.0 pose to the sector and the wider Cambodian economy?

The risk lies mainly in automation and the replacement of human labour by machines. The main cost factor in the garment sector is human labour which is why garments are mostly manufactured in developing countries with low labour costs. If the prices for robotics and machines decrease, the labour costs lose relevance. It means garment producers will move closer to the consumers. If that happens, low skilled workers in Cambodia are at risk of losing their jobs.

At what stage in the transition -towards a more high-tech ‘industry 4.0’ model- is the Cambodian garment sector at currently?

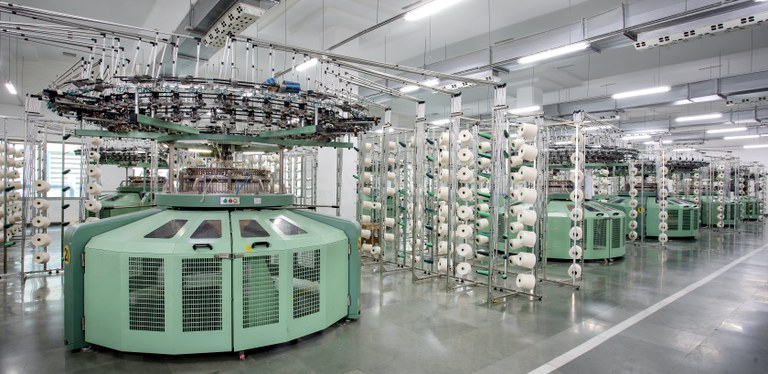

The Cambodian garment sector is still far away from Industry 4.0. Some processes are automated in the factories, but the machines are not connected to each other via the internet. It still requires human labour to operate.

If Industry 4.0 brings automation that replaces jobs with robots and other labour-saving technologies, what does this mean for garment workers in Cambodia, most of whom are low skilled women?

If they do not want to lose their jobs in the long-term, they need to upgrade and equip themselves with new skills and knowledge of modern technologies. As research shows, unfortunately, there is very limited awareness among low-skilled workers that they are at risk of losing their jobs.

What possible solutions or opportunities exist for workers in a more high-tech, automated garment sector?

There are many opportunities for workers, but in the end, it is all about learning. With the speed the economy is changing, we all need to keep up through lifelong learning. Five years from now, there is a high chance that complete different skill sets are needed in the economy. For the garment workers, it is important that they are aware of these quick changes and continue to invest in their education. It can be in the sector, e.g. learning how to run certain machines, or outside the sector, e.g. learning languages and other soft skills. Overall, the key thing is to learn how to learn.

Are industry stakeholders (e.g. government, brands or other organizations) providing any support to workers to help them manage the impact of this transition?

There are some initiatives discussed and implemented in recent years. The Cambodian Garment Manufacturers Association has a training center. However, personally, I don’t think the support is enough. In general, the Cambodian education system has to catch up with international standards. Universities need to move from pure teaching institutions toward research institutions. Education outside universities must be available for those who do not meet the requirements to attend colleges, like high standard and hands-on vocational training schools. An example is the high-quality vocational training system in Germany.

What risks and opportunities do garment manufacturers in Cambodia face amid the growth of Industry 4.0?

The risk for the garment manufactures is that the whole sector is moving to other countries with lower labour costs or in the long-run moving to garment factories that meet Industry 4.0 standards.

Is automation an imminent trend that firms (in Cambodia) will have to embrace, or will more traditional -labour intensive- production remain dominant for now?

It is all about production cost. At the moment, it is cheaper to produce in fully automated factories. The sector will move forward to it and workers will lose their jobs. It is a question of when it will happen.

And what about smaller (often local) garment manufacturers, which often lack the skills or capital to upgrade technologically. Will they survive Industry 4.0?

There will always be a place for ethical, local and hand-made garment products that follow certain standards. So some might survive the process without upgrading. The majority will not. You either invest to catch up, or you are at risk of running out of business.

In your report "The Risks of Industry 4.0 on Cambodia’s Garment Sector: Analysis and Ways Forward," you outline four possible scenarios for the sector. Talk us through these scenarios and tell us which one is most realistic (and why)?

I would distinguish between the most desirable and realistic scenarios. The most desirable scenario for the Cambodian economy is a “Fully Automated Garment Sector”. In this best case scenario there is also an opportunity for further growth, more and better paid jobs in this sector if there are more investments in skills and infrastructures, meaning the garment factories invest in automation as well as in the skills of their workers. The unqualified workers will lose their jobs, but the highly qualified workers will have a much higher income. The contribution to the Cambodian GDP and wealth will be high.

On the other hand, the most realistic scenario is a “Marginalized Garment Sector,” because of rising wages, a lack of automation and education. The Cambodian garment sector is losing its competitiveness. The garment production caravan is either moving to countries with cheaper labour or are fully automated and moving directly to customers in the developed countries. Just some small companies producing for local consumption will stay. There will be very limited contribution to the Cambodian GDP. The majority of the garment workers will lose their jobs.

Which approaches should policymakers / industry stakeholders adopt in order to ensure the whole industry in Cambodia benefits from the transition to Industry 4.0?

The Cambodian Garment Sector is at high risk of disappearing. It is therefore important to keep the sector competitive. The digital transformation is a chance to catch up, but the old hard ingredients for economic success like education and infrastructures are still essential to make Cambodia more competitive and desirable.

About Daniel Schmücking

Daniel Schmücking studied political science and sociology in Jena (Germany) and in Olomouc (Czech Republic). His professional and scientific focus is on political communication and election campaigns. From the beginning of 2015 until the end of 2017, he was the director of the Konrad Adenauer Foundation (KAS) foreign office in Mongolia. Since March 2018, he is the KAS Country Representative in Cambodia.